Automatic parts feeding

Flexmaster Pro

Components made of steel, aluminium or plastic often arrive unordered in a wire mesh box for the subsequent machining process. Until now, the (sometimes very heavy) components had to be removed by hand and fed to the downstream machine or a conveyor belt. This often resulted in cumbersome and ineffective work processes where additional separating stations had to be used. In addition, the employees were very physically strained.

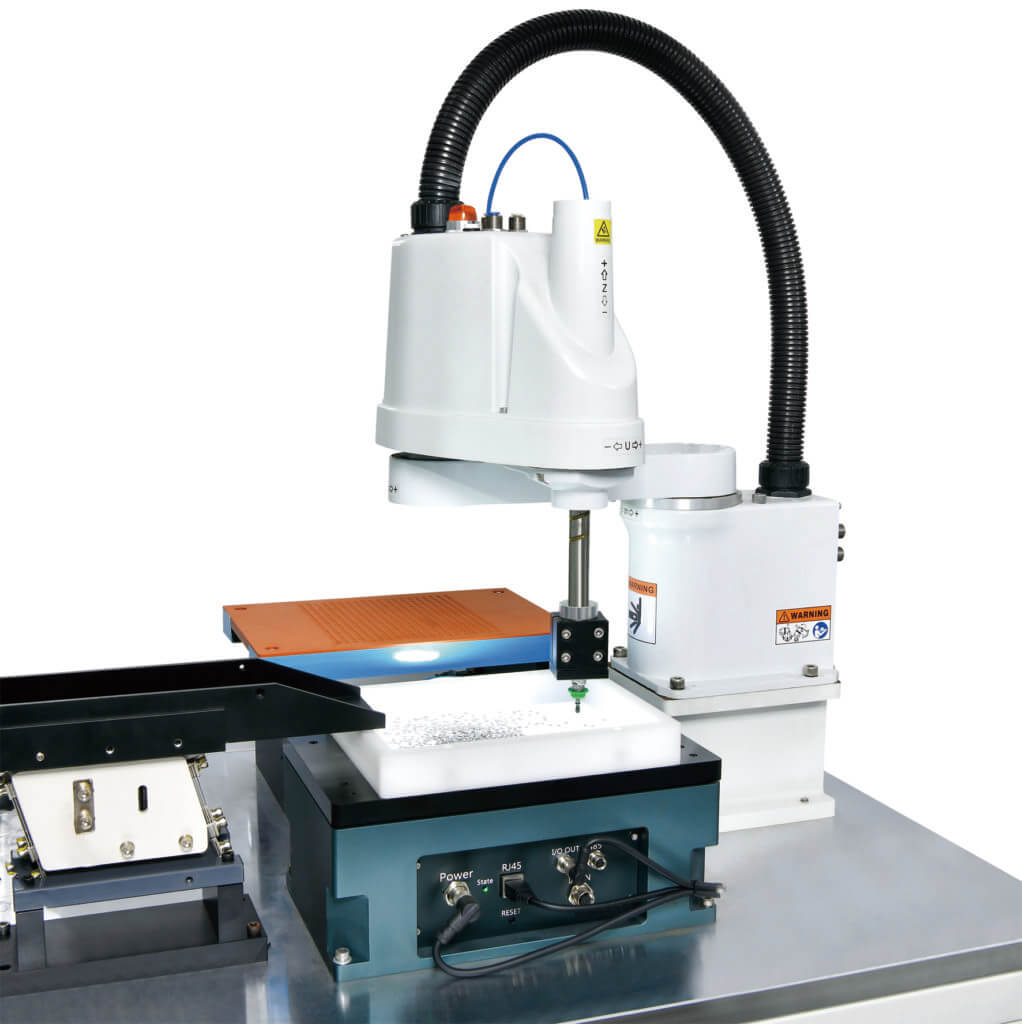

Flexmaster Pro is a flexible and automated feeding solution for handling bulk material and small parts. The system serves as an optimal link between robot and camera. Compared to classic solutions, the Flexmaster Pro offers a simple and intelligent software control for quick operation. The bulk material is provided in the correct shape and position for further use. Also suitable for frequently changing bulk material. Are you curious? Then ask us what a solution for your component might look like.

Flexible Production

Robots + Flexmaster

Optimum combination of flexibility and speed to ensure parts feeding even with changing bulk material.

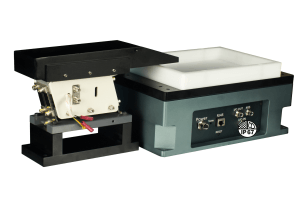

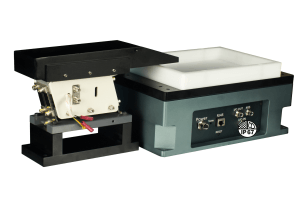

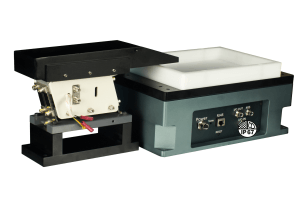

Feeder

Weitere Informationen >

JE-90

Tray: 71*111mm

Part size: ≤10g

JE-120

Tray: 89*120mm

Part size: ≤10g

JE-200

Tray: 156*208mm

Part size: ≤30g

JE-300

Tray: 210*280mm

Part size: ≤50g

JE-400

Tray: 265*336mm

Part size: ≤50g

JE-500

Tray: 341*488mm

Part size: ≤50g

Bunker

More information >

JE-1L

Drive Control: AC 220V

Volumen: 1L

JE-2L

Drive Control: AC 220V

Volumen: 2L

JE-3L

Drive Control: AC 220V

Volumen: 3L

JE-5L

Drive Control: AC 220V

Volumen: 5L

JE-10L

Drive Control: AC 220V

Volumen: 10L